Open for new ideas, enjoying in technical progress, always looking for more efficiency - these are KODA's qualities. Our customers benefit from our joy to innovate. We think along. And we also think ahead for the future. We are happy to rely on the support from the Institut für Umformtechnik und Leichtbau of the Technical University of Dortmund. Due to this good cooperation we already have completed several successful research projects.

The Background

In cooperation with the Institute for Forming Technology and Leightweight Construction (IUL) of the Technical University of Dortmun, KODA looked fpr approaches to reduce springback and press force. Why? The requests on the shape and dimensional accuracy of thinck-walled stamped and bent parts are constantly increasing. Unfortunately, however, the pressing force capacity is limited with ever larger components. A very encouraging approach was the local heating in order to be able to form the material in a softer state.

The technology

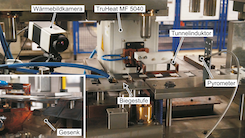

Based on this concept, a publicly-funded cooperation project was applied for at the Central Innovation Program for SMEs (ZIM) of the BMWi in 2012 and the "Indubend" project was approved. A progressive tool was developed within 2 years, which enables a significant reduction in flow stress and springback directly before forming by means of local inductive heating. The material to be processed becomes softer when heated, less force is required for its forming. The springing back of the component after reshaping is less and so undesirable form and dimensional deviations can be reduced. Tests on a micro-alloyed steel have shown the heated bending not only reduces springback, but also decreases internal stresses; at the same time, the structure and the material properties are not adversely affected.

See here a video (YouTube) of the technology.

The serial capability

Due to the integration of high-performance heating technology and innovative measuring and control systems, as well as a sophisticated design of the tool, high stroke rates are achieved that are comparable to conventional tools. The new technology fits the expectations of a series-capable process. Even it has additional potential for the production of high-strength components, because the process heat enables integrated heat treatment and thus the targeted setting of the local material properties in the forming process.

The potential of an economic application of the technology could be proven at the end of the project and led to the fact that the first automotive suppliers have already expressed interest in this innovative production route.

Follow up

The ConProBend project builds on the technology from the Indubend project, with the focus on influencing the local material properties in progressive tools. Semi-finished products are not only manufactured under reduced force and with reduced springback, but material properties are also specifically influenced by a coordinated temperature control - in the manner of a hardening process - and adjusted according to the later application.

The technology

In the two following years, the team worked on adjusting the product properties of high-strength sheet metal components in a regulated forming process and further developing this new technology to industrial maturity. The rapid heating, forming and cooling are the characteristics of this technology. These enable the hardening of low-alloy steels and also the press hardening of steels containing manganese-boron, with both high-strength and custom-made product properties being achievable in this process.

The new technology enables KODA to manufacture components from high-strength sheet steel, whereby the hard structural state only arises in the process after the forming by quenching in the tool. In contrast to the conventional production process at room temperature, hot forming expands the deformability of the material to be processed, which means that geometrically complex components can also be manufactured without splits.

The Patent

The new technology, developed with the IUL, was registered for a patent on February 10, 2014 and granted by the DPMA for Germany on October 19, 2017 (patent number DE102014001872B4). Before the patent was approved, the TU Dortmund transferred its shares to KODA.

Use in the automotive industry

In the spring of 2018, the first automotive supplier asked for a component that could not be manufactured using conventional methods or that could only be manufactured with great technical effort and expense.

Together with the customer, a production technology based on hot forming in the punching and bending tool and a component suitable for production and function was developed. Investments in the preliminary test tool, demonstrator component and live demonstration cemented the customer's wish for implementation and became more concrete with a customer order worth millions. The associated order also initiated the investment in an 800t servo press with a bar-transfer-system, which came into use at KODA in autumn 2019. The components have been run in series since spring 2020.

The backgrounds

In autumn 2015, KODA and its partners from research and industry applied for a project at the lead market agency of NRW in the program “Neue Werkstoffe.NRW” and the EU entitled “Development of hybrid plastic / magnesium material composites for ultralight construction applications - KuMag”. The research targets project was to develop a hybrid material made of magnesium and plastic. This combination is created by deep-drawing a wrought magnesium alloy and back-injection molding with thermoplastics. By combining magnesium and plastic to form a new type of hybrid material, the different material properties can be advantageously combined with one another.

The technology

The hybrid technology is based on a combined deep-drawing and back injection tool. In addition to a suitable connection technology for the plastic-magnesium connection, in particular through surface modifications of the magnesium component, tool concepts were developed for the preparation of the magnesium semi-finished products as well as for the integrated primary and forming of the new hybrid material. The KODA research focus was the investigation of the hot cutting of magnesium sheet materials as well as the co-development and construction of the new hybrid tool technology.

The new material connection is intended to enable the cost-effective production of lightweight and highly resilient structures with a high functional density. The project ended successfully in the summer of 2019 with the production of demonstrator components in the form of back-molded magnesium sheet metal parts.

Thanks to KODA´s participation in the project, KODA is prepared for possible applications in new markets and is well networked with the partners required for implementation.

The partners

KODA has been involved in a project funded by the Federal Ministry for Economic Affairs and Energy (BMWi) entitled “FUMAS - Function-integrated lightweight magnesium construction for car seat structures” since mid-2017. The target is to reduce the weight of a vehicle seat structure by using magnesium extruded profiles in the backrest, which is exposed to high mechanical pressure.

Project partners are the German Aerospace Center (DLR), an international automotive supplier for car seats, the Helmholtz Center Geesthacht (HZG) and JUBO Technologies GmbH. The main focus of the KODA participation is the forming - mainly hot bending - of magnesium extruded profiles.

The project was successfully completed in December 2020 with the production of demonstrator components in the form of a frame component designed as a magnesium-steel hybrid component.

What We Produce

Our product portfolio ranges from cabriolet solutions to window lift systems. More about our products. |

What we can do

More about our manufacturing. |

Who we are

More about us. |